- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: Fujian, China (Mainland)

- Brand Name: hengxing

- Model Number: wall panel machine

The production has advantages of solid, lightweight, thin, better strength, impact resistance, hanging strength , heat insulation, sound insulation, fireproofing, waterproofing, easy cutting environmental protection. It can be an arbitrary slot, without batch file, dry operation. Other wall materials can not reach our comprehensive advantages.

1.What's the Advantages of Light Weight Foamed Concrete block Making Machine ?

The production has advantages of solid, lightweight, thin, better strength, impact resistance, hanging strength , heat insulation, sound insulation, fireproofing,

waterproofing, easy cutting environmental protection. It can be an arbitrary slot, without batch file, dry operation. Other wall materials can not reach our comprehensive advantages.

2.What's the features of Light Weight Foamed Concrete block Making Machine ?

(1) Lightweight: weight of this wall panel is only 1/7 of the solid brick block which has the same size to it, thus to reduce the weight of buildings and lessen the load of the construction foundation.

(2) Strong: The capacity of buckling strength and the resistance of breaking load is twice to its ownweight.

(3) Low cost: the construction cost is lower than clay brick or cement block.

(4) It has advantages of resisting impact, fire proofing, and size accurate, convenient for nail, saw and so on.

(5) Unique construction joints between wall panels: Make sure that the wall is leveled off and verticalwhen seaming wall panels during the construction; meanwhile, the convexity and concave of thejoints enlarge the contact area, which enhances the stiffness and complete strength of the wall.

(6) The face board of this wall panel is made from fiber reinforced cement board, calcium silicateboard or other construction boards. It is a decorative wallboard which needn’t to be plastered; wecan dope and stick decoration to the wall directly.

(7) The thickness of the wallboard is reduced so it enlarges the usable area of the building.

(8) Adopt industry waste as material, so it can receives preferential policy of duty.

Raw material

Alumina cement, common Portland cement, fly ash/cinder, perlite, (wheat) straw, grain, saw dust, ceramic sand, flotsam EPS/polystyrene and admixture etc.

4.What's applacations of Light wall panel EPS foam sandwich panel making machine?

The wall panel can be widely used as un-load-bearing wall body in various of high and multi-storeys building,and also can be used for sound acoustical insulation, fire wall safety and practical uses. Once this product ispromoted in the market, they are immediately popular and welcomed in many builders and real estate agency. Because this wall panel not only owns satisfactory highquality performance, but also reduce wall occupied area,improve residential occupied area(every 100 square residential area increased 4 square of actual living space), reduce the structural load,improve the seismic safety of the building performance and reduce total cost and create most favorable value for you. It is a new breakthrough in wall material reformation in China.

- Place of Origin: Fujian, China (Mainland)

- Brand Name: hengxing

- Model Number: wall panel machine

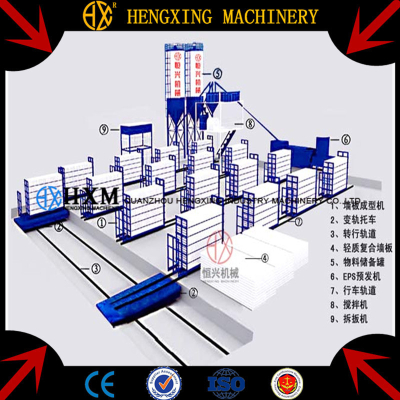

wall panel making machine technical parameters:

Function | feeding capacity | wall panel size | productivity of diffreent thickness | hydraulic unit | moulding cycle | machine weight | composition | ||

moulding device | 1.7m3 | 2440×600 ×75/90/100 /150/200mm | 75mm | 12pcs | motor power | 2.2kw | 2hours (alumina cement) | 5t | host machine

hydraulic unit

moulds |

90mm | 10pcs | piston daimter | φ80mm | ||||||

100mm | 9pcs | working route | 400mm | ||||||

150mm | 7pcs | working press | 3-4Mpa | ||||||

200mm | 5pcs | ||||||||

grouting container technical parameters:

function | grouting capaciy | working press | motor power | size | composition | |

transfer and press the material in the mixter inject into the moulding machine | 1m3 | 0.4Mpa | running motor: 1.1kw | air compressor motor: 3kw | 2755*1200* 1665mm | grouting machine running gear air compressor.pipeline |

| Model | JQ1000 Light Weight Aggregate Compulsory Mixer | |

| Performance | Type | Fixation |

| Charging Volume | 1700L | |

| Discharging Volume | 1000L | |

| Capacity | 20-23m³ /h | |

| Rotate Speed | 28r/min | |

| Maximum Aggregate Diameter | 5mm | |

| Water Weighing Accuracy | ≥ 2% | |

| Discharging Height | 2000mm | |

| Electromotor | Mixer | Y160L-6/11 |

| Lift Pot | Y100-4 | |

| Water Pump | 40ZBS-50-1.1 | |

| Frame Dimension | 5800× 2900× 5200(Length× Width× Height) | |

| Weight | 4700Kg | |