- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Size: based

- Place of Origin: Quanzhou, Fujian, China

- Brand Name: hengxing

- Model Number: AAC block making machine

- :

- :

- :

- :

- :

- :

- :

- :

- :

- :

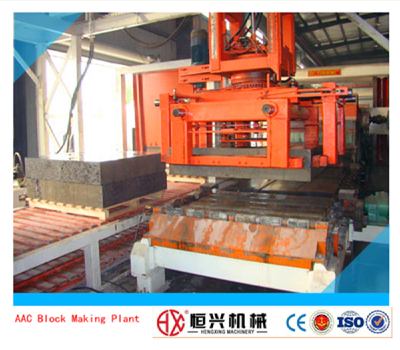

aac block machine and price aac block plant aac block cutting machine

(1)light weight

Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as

1/3 of clay brick and 1/5 common concrete.So use the Light brick can reduce the weight of the

build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the

material and cost,it also fighting shaking.

(2) keeping temperature

It has many are porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or

1/5 of clay brick,so it is best materials now in the world.There are many kinds material,have

lowest waste.

(3)High Strength

High pressure steam-curing autoclaving process gives AAC unmatchable strength to weight ratio, higher than even M150 concrete and far exceeds the Indian Building code requirements

(4)Cost saving

Being lightweight AAC drastically reduces the dead weight of building, resulting into reduction in steel (up to 27%) and cement (up to 20%) structural cost saving.

Being 8 times the size of a clay brick, AAC wall construction involves 1/3 the joints, thus an overall mortar saving up to 66%

- Size: based

- Place of Origin: Quanzhou, Fujian, China

- Brand Name: hengxing

- Model Number: AAC block making machine

- :

- :

- :

- :

- :

- :

- :

- :

- :

- :

| 1) Factory covers an area of 25 acres or so. |

| 2) There should be raw material area, finished block area and production area. |

| 3) Production process includes raw material disposal, rated material pouring, curing, cutting and steaming procedure . |

| 4) From building foundation to equipments installing and testing, and to trial producing, it will take 4-5 months. |

5) Plant design: 2000m2 or so. |

6) Raw material for making AAC Block: Cement, Lime, Sand, Gypsum, Aluminum powder, and Water. |

Capacity of AAC production line AAC block machine per year: 50,000m3, 100,000m3, 150,000m3, 200,000m3, 300,000m3.